Locating the Right Provider for Welding Inspection Madison: Trick Considerations

Locating the Right Provider for Welding Inspection Madison: Trick Considerations

Blog Article

Exactly How Reliable Welding Inspection Improves Architectural Honesty and Durability

In the realm of building and construction and engineering, the relevance of welding examination can not be overemphasized, as it plays a crucial role in ensuring architectural integrity and prolonging the lifespan of jobs. By releasing a series of innovative evaluation techniques, such as ultrasonic and radiographic testing, professionals can determine issues that may jeopardize the integrity of a framework. Nevertheless, the inquiry continues to be: exactly how do these precise processes equate into tangible advantages for durability and safety and security? Sign up with the exploration of just how effective welding evaluations can change prospective susceptabilities into toughness, adding to the enduring success of constructions.

Relevance of Welding Inspection

Making sure the architectural honesty and security of bonded buildings mandates rigorous welding inspection processes. Welding assessment acts as a crucial protect in the building and construction and manufacturing markets, where the toughness and sturdiness of joints considerably influence the total performance of frameworks. This inspection guarantees that welds satisfy specific criteria and specs, lessening the dangers linked with architectural failures. The consequences of inadequate welds can be tragic, causing costly repair services, functional downtimes, or even tragic failings, all of which highlight the critical importance of comprehensive inspection.

In enhancement to safety and security, welding examination plays a crucial duty in quality guarantee. By adhering to predetermined criteria, inspections identify the uniformity of welds, making sure that each satisfies the desired toughness and visual demands. This consistency is crucial not just for security however also for preserving the track record and dependability of manufacturers and builders. Regulative compliance is a considerable vehicle driver of welding evaluation techniques. Industry criteria and codes, such as those from the American Welding Society (AWS) or the International Company for Standardization (ISO), necessitate adherence to strict guidelines, highlighting the value of inspections in fulfilling these expert and lawful obligations.

Trick Examination Methods

Ultrasonic Checking (UT) makes use of high-frequency acoustic waves to find subsurface defects, supplying precise info concerning weld honesty without triggering any damage. Radiographic Evaluating (RT), entailing X-rays or gamma rays, supplies a detailed photo of the weld's interior structure, disclosing concealed blemishes. Magnetic Fragment Testing (MPT) is another non-destructive technique, specifically effective for finding surface area and near-surface suspensions in ferromagnetic products.

Penetrant Testing (PT) involves the application of a liquid dye to reveal surface-breaking problems, supplying a cost-effective and straightforward service for non-porous materials. Each strategy has its certain applications, staminas, and constraints, and typically a combination of methods is employed to achieve comprehensive evaluation results. Proficiency of these strategies improves the integrity and durability of bonded frameworks, lining up with safety and performance expectations.

Identifying Common Problems

Porosity, defined by gas pockets within the weld, lowers the weld's toughness and durability. Fractures, which can happen throughout or after welding, posture substantial risks due to their potential to propagate under tension.

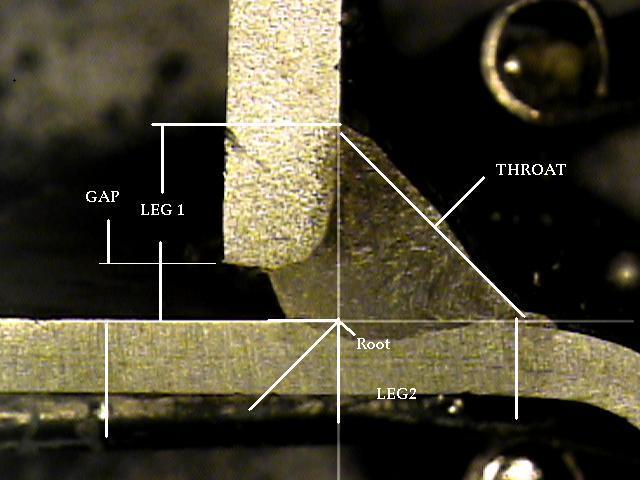

Insufficient combination, where the weld steel falls short to bond entirely with the base product, undermines the structural honesty, bring about weak joints. This defect generally comes from not enough heat input or improper welding technique. Slag inclusions occur when non-metallic materials are caught in the weld, jeopardizing its stamina and high quality. These are commonly a result of insufficient cleansing in between weld passes or incorrect flux usage.

Recognizing these issues with careful examination techniques, such as visual evaluation, ultrasonic screening, or radiography, is critical. Addressing these concerns makes certain weld top quality, eventually supporting the architectural honesty and safety and security of the developed environment.

Enhancing Architectural Performance

Recognizing the significance of recognizing typical weld issues naturally brings about exploring methods for improving structural efficiency. The foundational approach for enhancing efficiency entails utilizing innovative welding strategies and products that mitigate problem incident. Making use of premium filler products and making certain proper heat control can significantly minimize issues such as porosity and breaking, thereby improving the weld's integrity.

Incorporating cutting edge welding innovations, such as laser welding and rubbing mix welding, additional enhances structural more tips here resilience. These methods provide superior precision and reduced thermal distortion, straight affecting the toughness and strength of the bonded structures. Embracing automated welding systems can make sure repeatable and regular weld high quality, minimizing human error.

Furthermore, carrying out extensive pre-weld and post-weld treatments is vital. Proper joint style, surface prep work, and stress-relieving processes add to optimum weld efficiency. Conducting thorough pre-weld examinations enables early detection of possible issues, promoting timely adjustments prior to they endanger the structure.

Long-lasting Advantages of Assessment

Through attentive evaluation techniques, the long-term advantages to architectural integrity become progressively obvious. Consistent and comprehensive welding inspections play an essential function in protecting against structural failures by identifying incongruities and issues early in the building process. This proactive technique makes sure that prospective problems are addressed prior to they can jeopardize the safety and longevity of structures. By catching defects early, expensive repairs and downtime are decreased, eventually prolonging the life-span of the infrastructure.

Moreover, regular inspections add to maintaining compliance with industry standards and policies, consequently staying clear of monetary and legal consequences. This adherence to quality control not just boosts the integrity of the framework yet likewise cultivates depend on amongst stakeholders, including clients, engineers, and regulatory bodies. The extensive documentation of evaluation outcomes functions as a beneficial source for future upkeep and repair service efforts, helping with informed decision-making.

Furthermore, effective inspection techniques sustain development by incorporating innovative technologies such as non-destructive screening and digital imaging, which can improve precision and effectiveness. This technical integration better emphasizes the commitment to quality in structural honesty. Inevitably, spending in careful welding inspections is a sensible method that yields significant long-lasting advantages, safeguarding both the physical and monetary investment in facilities tasks.

Final Thought

Effective welding evaluation plays a vital role in improving Homepage structural honesty and long life by determining issues early in the building procedure. Utilizing techniques such as visual inspection, ultrasonic testing, and radiographic screening guarantees the discovery of issues like cracks and porosity that endanger weld strength. Extensive examinations guarantee compliance with industry requirements, therefore prolonging the life-span of frameworks, reducing costly repair services, and promoting stakeholder count on the reliability and security of bonded buildings.

In the world of building and construction and engineering, the value of welding examination can not be overstated, as it plays a pivotal role in making sure architectural find more honesty and extending the life-span of jobs.Ensuring the structural stability and security of welded building and constructions requireds rigorous welding evaluation procedures.Building upon the relevance of welding evaluation in securing architectural stability, comprehending the vital inspection techniques becomes necessary for reliable execution. Effective welding inspection encompasses a range of approaches made to assess weld top quality, ensuring conformity with stringent design criteria - Welding Inspection Madison.Reliable welding assessment plays an essential duty in improving architectural stability and durability by identifying issues early in the building and construction procedure

Report this page